For Australian business owners and facility managers, fire safety compliance is often a source of anxiety. The regulations can seem dense, the fines for non-compliance are severe, and the costs of external contractors continue to rise.

This guide clarifies exactly what is required under AS 1851-2012, explains who is legally permitted to check your equipment, and reveals how upskilling your own staff with Skylar Education can significantly reduce your compliance costs.

The Hierarchy of Compliance: Who Makes the Rules?

To understand your obligations, you must first understand the regulatory landscape. It is not just about “following the rules”; it is about understanding how Acts, Regulations, and Standards interact to create your legal duty of care.

At the top is the Work Health and Safety (WHS) Act, which mandates a “non-delegable duty of care” to provide a safe workplace. Beneath this are the Regulations that enforce these duties, and finally, the National Construction Code (NCC) and Australian Standards (like AS 1851) that provide the technical “how-to.”

The Regulatory Pyramid: WHS Laws and the NCC set the mandatory requirements, while AS 1851 provides the technical methodology. The ‘Competent Person’ is the foundational execution layer required to satisfy all

Failure to comply with these layers doesn’t just risk a fine; it risks prosecution for negligence. In Victoria alone, penalties for failing to provide a safe system of work can reach $370,000 for a body corporate.

The 6-Month Rule: Your Maintenance Schedule Explained

The most common question we hear is: “How often do I need to test my fire extinguishers?”

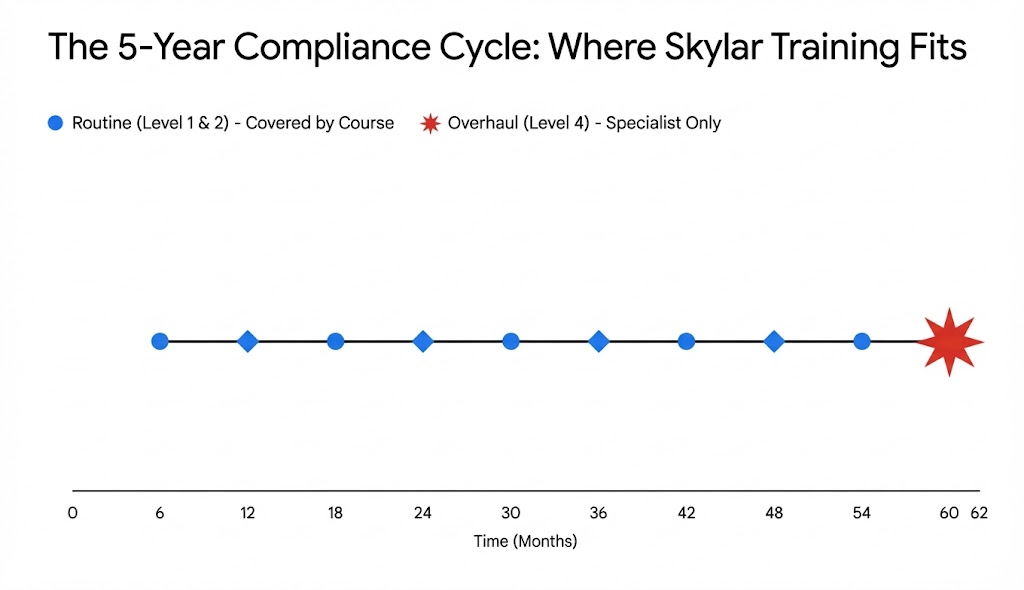

According to AS 1851-2012 Routine service of fire protection systems and equipment, the standard service interval is every six months.

While some checks are simple, the schedule increases in complexity over time.

- Level 1 (Every 6 Months): Routine inspection. Checks include accessibility, signage, pressure gauge readings, weight verification, and anti-tamper seal integrity.

- Level 2 (Yearly): Includes all Level 1 checks plus more detailed inspections of the hose, nozzle, and support bracket.

- Level 4 (Every 5 Years): A critical overhaul. The extinguisher must be emptied and subjected to a hydrostatic pressure test.

<!– Info Box / Callout Block –>

Key Takeaway: The CPPFES2020 Conduct Routine Inspection and Testing of Fire Extinguishers and Fire Blankets course covers the skills required for Level 1 and Level 2 inspections. This means a trained staff member can legally handle your compliance needs for 4 out of every 5 years.

The “Competent Person”: Can We Do It In-House?

There is a widespread myth that you must hire an external contractor to inspect your fire extinguishers. This is false.

AS 1851 defines a “Competent Person” as someone who has acquired the knowledge and skill to perform the task through training, qualification, or experience.

For routine monthly and six-monthly inspections, you do not necessarily need an external specialist. You need a competent person.

By enrolling a staff member in the CPPFES2020 course with Skylar Education, you provide them with the formal qualification to demonstrate this competency. This allows you to bring the testing regime in-house, ensuring you are always compliant without waiting for a contractor to turn up.

Strategic Decision: Train vs. Outsource

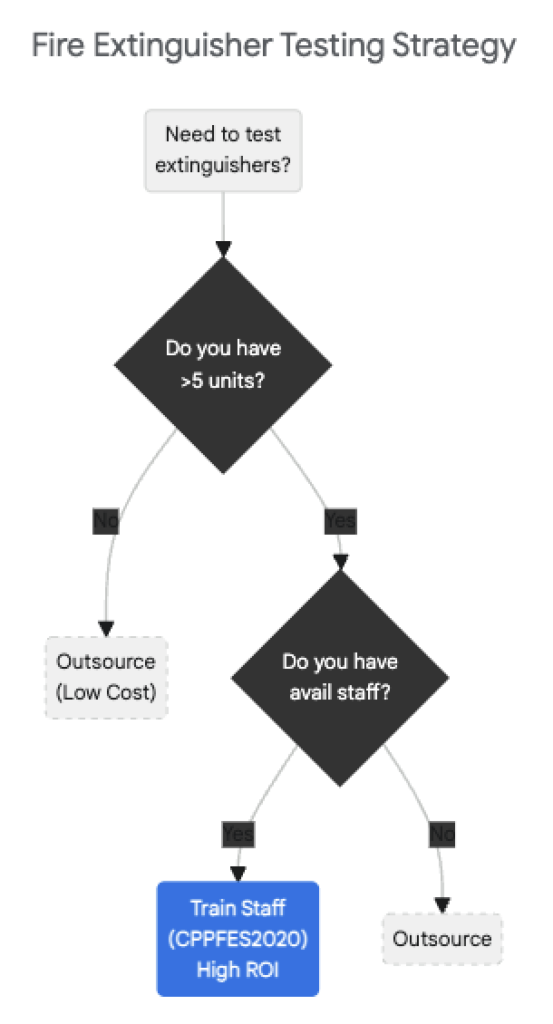

Is it worth training your own staff? For most businesses with more than a handful of extinguishers, the answer is a resounding yes.

[Insert Graphic: Bar chart comparing 5-year costs of External Contractors vs. In-House Training] Alt Text: Cost comparison chart showing significant savings by using in-house staff for routine testing.

Decision Guide: Train In-House or Outsource?

The Economics:

- External Cost: A contractor may charge a $100 call-out fee plus $15–$20 per extinguisher. For a site with 20 units, that is ~$800 annually.

- In-House Cost: The Skylar CPPFES2020 course is a one-off investment of $180. The ongoing labour cost is just minutes of staff time per month.

Know Your Equipment: A Compatibility Matrix

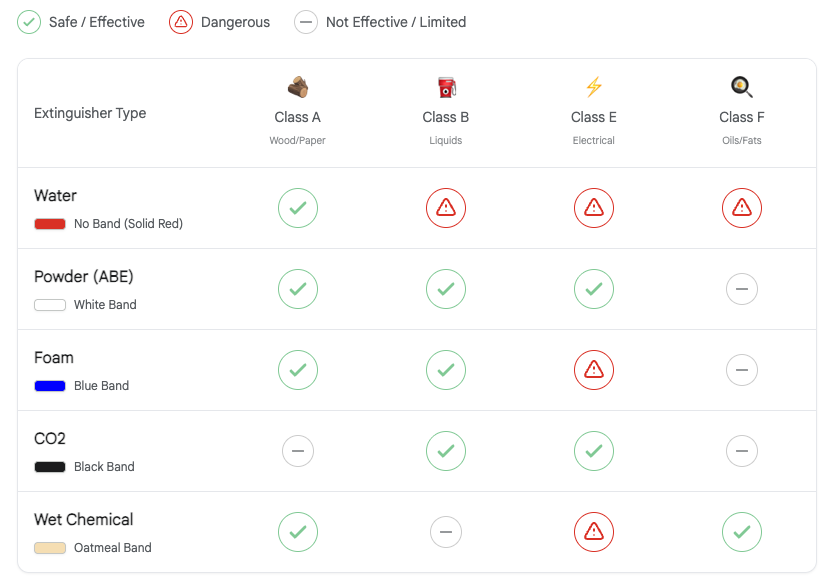

Part of being a “Competent Person” is ensuring the right extinguisher is available for the specific risks in your workplace. Using the wrong extinguisher can be fatal—for example, using a water extinguisher on an electrical fire (Class E) puts the operator at risk of electrocution.

Refer to the matrix below to ensure your site is equipped correctly.

Fire Extinguisher Compatibility Matrix

Identify the correct extinguisher by its colored band

The Skylar Solution: Compliance Through Education

Reliance on external vendors creates a “compliance blind spot.” You assume everything is correct because you pay a bill, but you ultimately bear the liability.

Taking control of your fire safety strategy creates a safer, more responsive workplace. Skylar Education offers two key pathways to achieve this:

- (Conduct Routine Inspection & Testing of Fire Extinguisher & Fire Blankets)

- Cost: $180

- Outcome: Qualifies staff to perform routine 6-monthly and annual inspections, fill out logbooks, and punch service tags (Unit CPPFES2020).

- Format: Blended learning (Online theory + 1-day practical).

- (Fire Extinguisher & Emergency Warden)

- Cost: $335

- Outcome: Combines the technical inspection skills with the leadership training required to coordinate an evacuation (Units PUAFER005 & PUAFER006).

By upskilling your team, you move from “paying for compliance” to “owning safety.”

Disclaimer: Licensing requirements vary by state. In Queensland, specific QBCC licenses are required for most fire protection work. Always check with your local regulatory body.